Well… finally getting around to starting HELEN, the tender for BISH. As I mentioned earlier, BISH was my father’s nickname. HELEN is my mother. They are both long gone from this earth, but hopefully will live on together in the form of traditional wooden boats…built with love by their son. HELEN was originally designed by Murray Peterson of Maine for use with his SUSAN (sister-ship to BISH). The plans have been updated by his son, Bill Peterson. She will be built of Port Orford Cedar… the left-overs from the BISH build. The floors and planks will be steam-bent into shape. There is no timetable for this build. I will get to it when I get to it. The builders age is the main constraint.

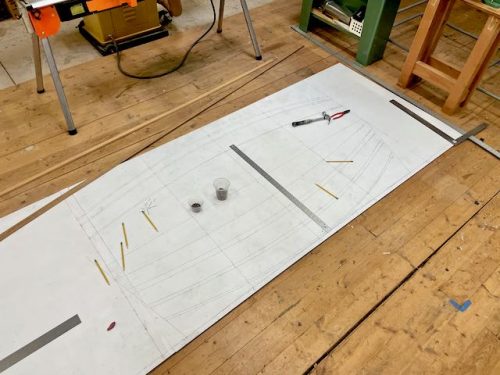

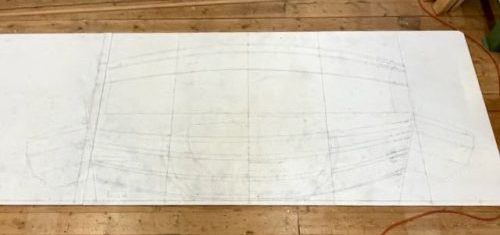

From the plans, I have drawn out the profile and half-breaths of the new boat on 2 4×8 sheets of plywood painted white.

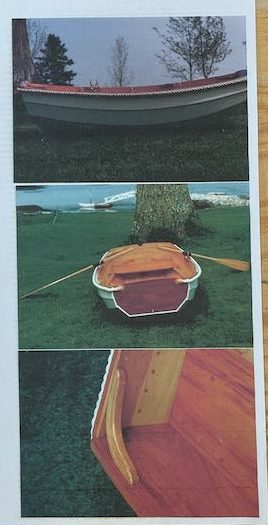

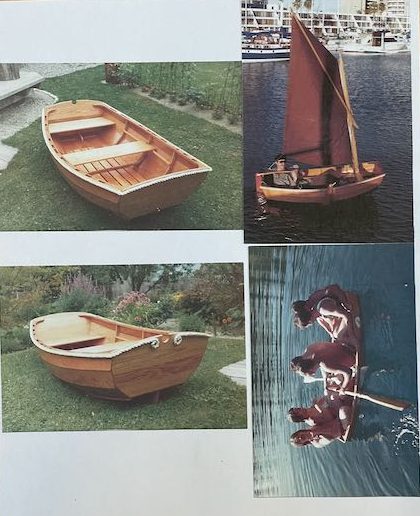

Here are pictures of earlier builds of the pram. HELEN will be painted to match BISH and have varnished bow and transom.

From the lofting of the offsets, I put drywall nails on their sides along the lines and pressed plywood against them to show the lines on the plywood. Then using a batten redrew the lines on the plywood, cut them out and duplicated the piece to make one complete mold.

Next up: build the strongback. The pram is built on top of this. The bottom is set on this support and temporarily secured to it. The molds sit on these bottom planks.

These are the floor planks. They are 5/8″ thick by 7′ long. They are tongue-and-grooved together. Each will first be steamed and clamped to the strongback to get their form set. Then attached together to form the floor. The skeg keel is shown where it will be attached after the floor is assembled. It is made of white oak (to take up the scratches from groundings).

OK. The cedar floor planks have now been steamed and bent onto the strongback.

I’ll let them set up for a couple days.

After setting up, I applied a bead of 5200 to both sides of the tongue and inserted each tongue into the appropriate groove of the adjacent piece. Clamped it all together and now will let the 5200 setup. This can take a couple weeks, which is fine as there is still some snow in Sun Valley for some snow-showing and cross-country skiing.

Next step… build a framework capable of stabilizing the molds, plus bow and stern transoms. The transoms are two-part mahogany.

Recent Comments